-

+86-757-85586781Tel

-

419329352@qq.comE-mail

-

+86-757-85552182Fax

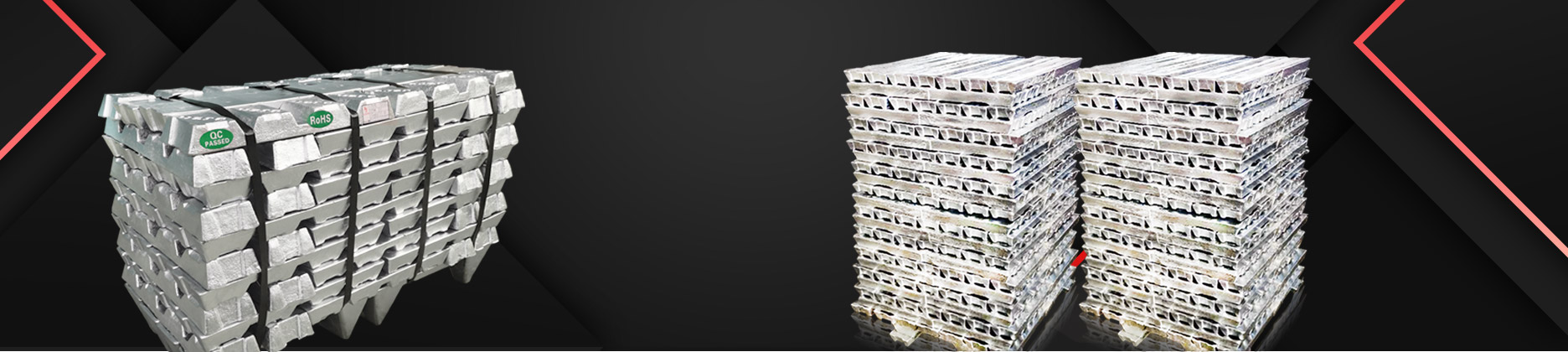

Die casting die forging of aluminum alloy ingot is a kind of processing technology. Firstly, the liquid metal is poured into the die cavity at low speed or high speed. With the cooling process of the liquid metal, the shrinkage defects of the blank can be eliminated, and the internal structure of the blank can reach the broken grains in the forging state, and the comprehensive mechanical properties of the blank can be significantly improved. The advantages of die casting and die forging of aluminum alloy ingot: in addition to traditional casting materials, it can also use deformation alloy and forging alloy to produce parts with complex structure, and the strength of these materials is much higher than that of ordinary casting alloy.

Die casting die forging of aluminum alloy ingot is very important in the production of aluminum alloy die casting. The correct and reasonable die structure is the prerequisite for the smooth production of aluminum alloy ingot die casting, and plays an important role in ensuring the quality of the casting. However, when the aluminum alloy ingot is die-casting and forging, the high-quality casting of the production process is closely related to the mold design, which is essentially a comprehensive reflection of various factors that may appear in the aluminum alloy ingot die-casting production. The reasonable design of aluminum alloy ingot mould determines the qualified rate of casting.